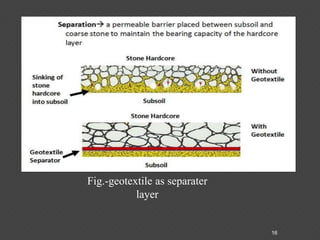

A major initiative in pavement design was the development and implementation of the Mechanistic-Empirical M-E methods. Al-Qadis design method suggests that when a geotextile is placed in a pavement as a separator the range of the total pavement life cycle cost savings can be as high as 70 to as low as 40.

Geotextiles prevent the mixing of the fine subgrade soils with the aggregate support layer.

. View 1602747002582_PAVEMENT DESIGN OF USING GEOTEXTILEpptx from CE MISC at JSPMS Imperial College of Engineering Research Pune. While the M-E Pavement Design Guides MEPDG have been officially adopted eg Australia 2004 and AASHTO 2008 these guides do not include the evaluation of pavement performance when. Topics For Seminar March 13 2014.

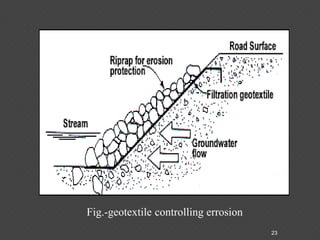

A geotextile may be made of synthetic or natural fibers. A geotextile is defined as any permeable textile material that is used with foundation soil rock earth etc to increase stability and decrease wind and water erosion. Specifically geosynthetics have been used for separation Zornberg JG.

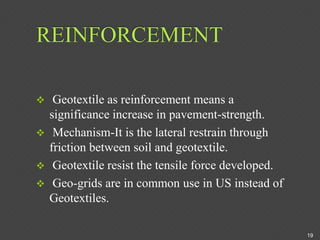

2332 The strip methodis primarily used on Portland cement concrete PCC pavements and involves preparing the existing cracks and joints and placing a 12 to 24 inch wide geotextile and sufficient asphalt directly on the cracks and joints. GEOSYNThETiCS iN PAvEmENT dESiGN Geosynthetics have been used in pavement design to address the functions of separation filtration lateral drainage sealing and reinforcement. Pavement design by using geotextile ppt Coffin nails have become the hottest manicure pattern at the moment thats heading nowhere fastBlack appears to be best with any color.

Pavement Design By Using Geotextile Ppt. JSPMS RAJARSHRI SHAHU COLLEE. A geotextile is defined as a permeable.

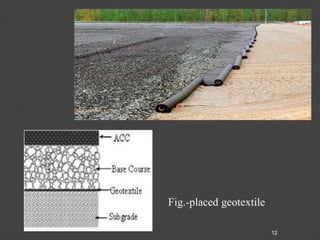

Types of geotextiles-Geotextiles are usually made from polymers such as polyester or polypropyleneFurther prepared in 3 different categories- 1Woven type 2Non-woven type 3Knitted type4 1WOVEN TYPE GEOTEXTILEThese were the first to be developed from the synthetic fibersManufactured with a process of weaving narrow strip of film together to. Pavements typically consist of a bituminous or concrete surface aggregate base layer or support layer and then the natural soil subgrade. This depends on the selected design alternative.

CBR 3 and shear strength between approximately 30 to 90 kPa. Advances in the Use of Geosynthetic in Pavement Design. During the last 20 years of the 20th century the use of geotextiles spread geographically worldwide and in area terms their use increased almost exponentiallyMuch confusion is evident throughout typical design sources regarding geotextiles themselves as well as applications relevant to roadway design.

Function in pavements. Materials in pavement design. Geotextile construction damage decreases exponentially with an increase in mass per unit area.

And retain the design strength up to at least 4 years for tidal rivers with two-way flows and 2 years for one-way flow. In contrast a geomembrane is a continuous membrane-type liner or barrier Geomembranes must. The primary design consideration for such geotextile are construction survivability and soil retention.

The stabilization function of geotextile is applicable to pavement structures constructed over soils with a California Bearing Ratio between 1 and 3 1. Geotextile apparent opening size is related by a factor of 12 to 1 with d85 size of the soil being retained.

0 komentar

Posting Komentar